Panel Systems – Citadel Envelope 2000®

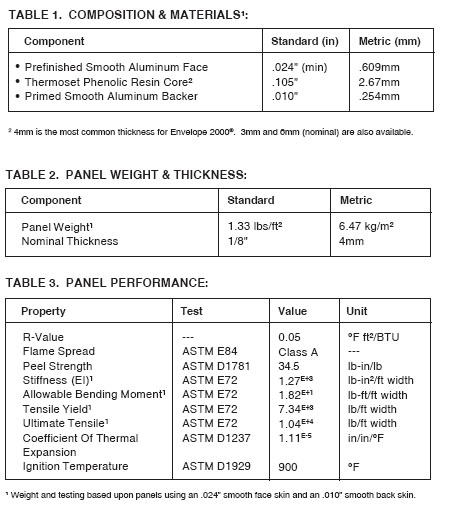

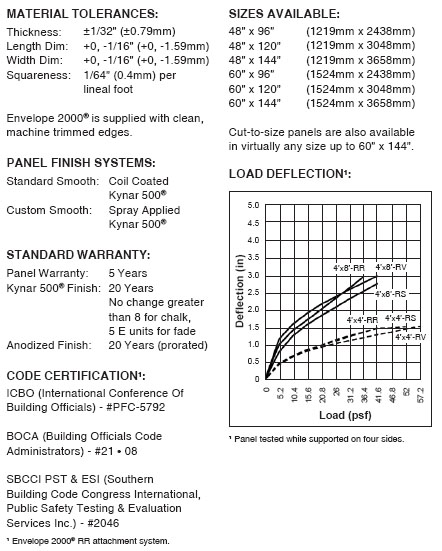

Envelope 2000® is a fabricated wall system utilizing a composite panel made by laminating a prefinished aluminum skin to a substrate of thermoset phenolic resin. A second aluminum skin is added as a backer and provides thermal stability and panel balance. Panels are furnished with a strippable film on the painted surfaces to protect the finish during shipment and installation. Envelope 2000® is fabricated and then attached to the substrate with a series of aluminum extrusions. The three basic attachment methods for Envelope 2000® are the Reveal System (RV) utilizing one piece extruded aluminum moldings, the Rout & Return System (RR) with formed ‘pans’ and attachment extrusions and the RainScreen System (RS) utilizing formed ‘pans’, attachment extrusions and featuring ‘dry’ joints.

Envelope 2000® is a fabricated wall system utilizing a composite panel made by laminating a prefinished aluminum skin to a substrate of thermoset phenolic resin. A second aluminum skin is added as a backer and provides thermal stability and panel balance. Panels are furnished with a strippable film on the painted surfaces to protect the finish during shipment and installation. Envelope 2000® is fabricated and then attached to the substrate with a series of aluminum extrusions. The three basic attachment methods for Envelope 2000® are the Reveal System (RV) utilizing one piece extruded aluminum moldings, the Rout & Return System (RR) with formed ‘pans’ and attachment extrusions and the RainScreen System (RS) utilizing formed ‘pans’, attachment extrusions and featuring ‘dry’ joints.

Product Data Sheet | Cad Drawings | Installation Guidelines

BASIC USES & APPLICATIONS

As a high end fabricated system, Envelope 2000® is designed for use as an exterior cladding on walls, canopies, fascia, and accent bands. Envelope 2000® is typically used on medium to high rise buildings, such as office towers, retail complexes, educational buildings, medical facilities, etc…

FEATURES & BENEFITS:

As a complete exterior cladding system, Envelope 2000® offers a number of benefits to the building owner, architect, and installer including:

- High-Tech Appearance

Smooth aluminum skins and clean lines make Envelope 2000® an excellent choice for high profile projects where a progressive aesthetic detail is desired. - Versatile Installation

With three different attachment options, virtually any look can be created using different shadow line sizes and treatments at the panel joints. - Curveable

Along with various shadow lines, Envelope 2000® can also add interest to your project with long sweeping curves or tight, crisp column covers. - Thermal Stability

Unlike other cladding solutions, Envelope 2000® systems remain rigid and stable even during seasonal heating and cooling thermal cycles. - Durable

An innovative thermoset phenolic resin core provides these panels with superior impact and dent resistance. - Low Maintenance

Most foreign matter can be cleaned from surface with mild detergents; can be incorporated into yearly building washing schedule.

GENERAL LIMITATIONS:

Envelope 2000® is intended for use as an exterior cladding. It is not eligible for use as a structural element of a wall assembly. Envelope 2000® should not be used in applications where the slope exceeds 25° from vertical.

SYSTEM FINISHES:

Envelope 2000® comes standard with a smooth aluminum skin. Standard and metallic colors are furnished with a durable Kynar 500® coating. Anodized finishes are available as a standard finish. Custom colors are also available to match customer’s standard. Moldings (Reveal System) are coated using a Kynar 500® paint system and can be painted to match any standard or custom color.

REVEAL SYSTEM (RV):

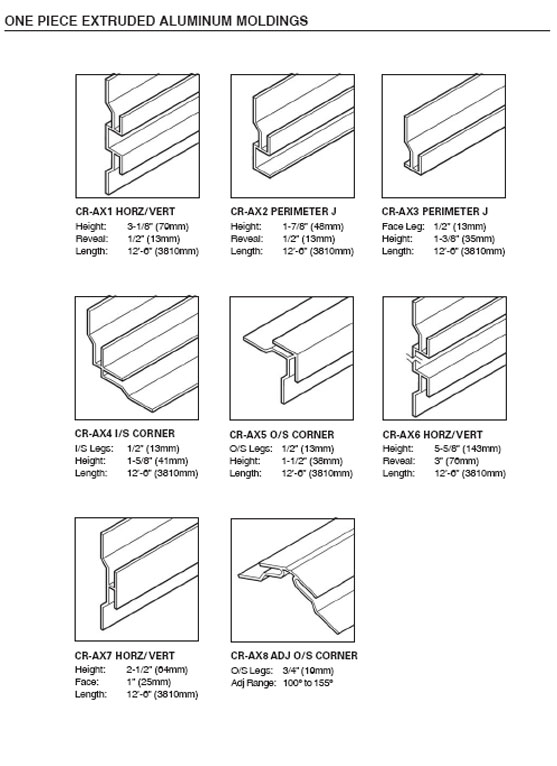

Utilizing one piece extruded aluminum moldings, this is a barrier system that features a progressive installation. The moldings are mechanically fastened to the substrate. The panels are then inserted into the moldings, along with sealant and attached to the substrate using construction adhesive at intermediate locations. Reveal (1/2” typical, 3” also available) and batten profile moldings are standard.

ROUT & RETURN SYSTEM (RR):

Barrier system in which panels are fabricated and formed into ‘pans’ and then ‘hung’ on the substrate using aluminum extrusions. All fasteners are concealed and panel joints (1/2” reveal typical) are finished with an approved sealant.

RAINSCREEN SYSTEM (RS):

Based on the ‘rainscreen principle’, this system allows incidental water to enter the cladding cavity, but then be drained through the system via weepholes. Also utilizing formed panels, this system is attached using aluminum extrusions. Panel joints are finished using color matched or complementary accent strips that ‘float’ in the extrusions providing a reveal from 1/2” to 12”.